Hexon Hot Stage Microscope

Why hot stage Microscopy compared to conventional

Hot stage microscopy is preferred over conventional microscopy because it combines real-time visual observation with precise temperature control, enabling dynamic study of thermal transitions and structural changes that are not possible with standard microscopy. This advanced technique provides researchers with the ability to analyze materials as they are subjected to heating or cooling, allowing direct, in-situ observation of events such as melting, crystallization, phase transitions, and polymorphism that are critical in fields like pharmaceuticals, materials science, and nanotechnology

Advantages Over Conventional Microscopy

- Thermal Control: Hot stage microscopy allows controlled heating and cooling, often in a programmable manner, across wide temperature ranges (e.g., −40 °C to 600 °C), something not possible in conventional microscopy.

- Real-Time Observation of Transitions: The technique enables the observation of dynamic processes such as melting, crystallization, desolvation, and glass transitions as they occur, providing insight into both structural and chemical changes within the sample.

- Enhanced Phase Transition Detection: While traditional thermal analysis techniques like DSC and TGA provide numerical data on phase transitions, hot stage microscopy visually reveals even minor changes that might be missed, reducing ambiguities and misinterpretations.

- Complementary and Stand-alone Uses: Hot stage microscopy is often used alongside other analysis tools (e.g., FTIR, Raman, X-ray, SEM) for a comprehensive characterization, but it can also serve as a stand-alone technique for solid-state studies and quality control.

- Versatility: Suitable for a broad range of materials—polymers, pharmaceuticals, metals, catalysts, and even nanomaterials—hot stage systems offer flexible sample environments (open, closed, inert, oxidizing, etc.).

Why Researchers Prefer Hot Stage Microscopy

- Visual Data with Context: It visually documents how materials change under thermal stress, offering a deeper understanding of morphology, phase behaviour, and defects.

- Rapid and Accurate: Data is obtained rapidly with less potential for operator error, saving time in research and quality control.

- Coupling with Analytical Software: Modern systems include digital imaging, analysis software, and programmable heating/cooling cycles for precise, reproducible studies.

Hexon Hot Stage

Hexon Instruments offers advanced hot stage microscopy solutions that combine precise temperature control with microscopy techniques for material analysis, especially in pharmaceutical applications.

Hexon hot stage microscopes feature software-controlled temperature ramping, allowing controlled heating and cooling with the ability to observe samples in bright field, dark field, and polarized light. Hexon hot stage microscopes can capture high-frame-rate images and videos with temperature, date, time, and micron markers.

Hexon hot stage enables homogeneous heating of samples on glass slides and supports controlled cooling and gas purge for varied environmental conditions. Hexon’s hot stages cover a wide temperature range from -40 to 600 degrees Celsius, making them suitable for various research and industrial purposes including polymer and plastic thermal analysis and pharma solid-state characterization

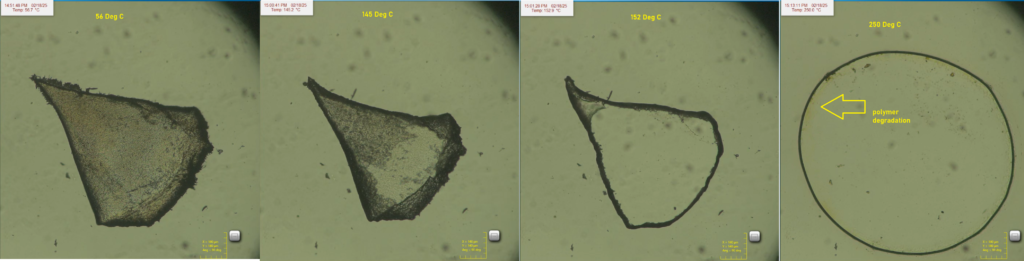

Polymer Sample

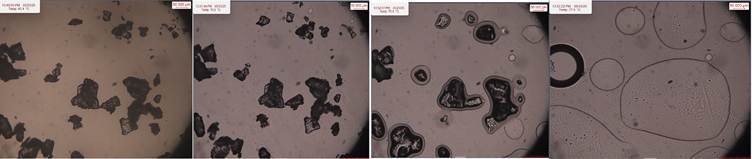

Ibuprofen sample

Hexon Hot Stage is compatible with all types of Microscopes.

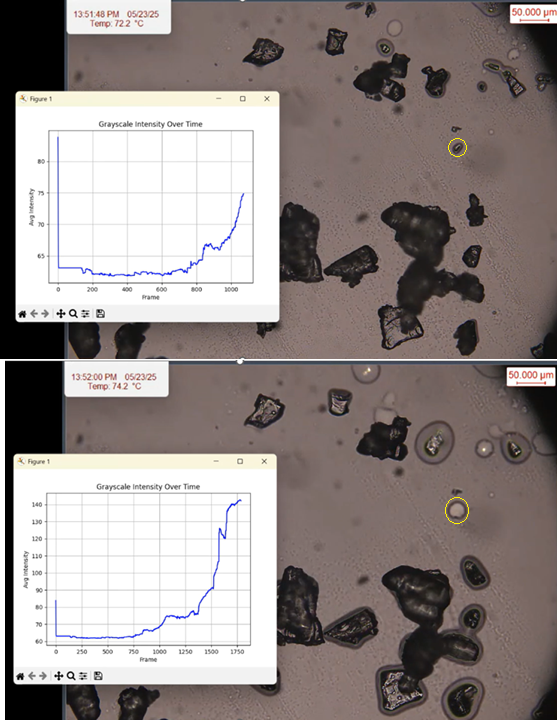

Analyse surface of sample and create intensity plot

Hexon instruments have launched unique software to work with Hexon Hot stage for Analysing surface of sample and create intensity plot against Temperature

Hexon Hot stage Thermal analysis combined with surface characterization allows for a comprehensive understanding of how material properties change with temperature, crucial for developing and optimizing advanced materials in fields such as polymers, metals, catalysts, and pharmaceuticals.

We believe the Hexon hot stage system could greatly enhance your thermal analysis capabilities.

We would like to demonstrate our system, capabilities for your research application.

Lets connect!