Electric Discharge Drilling Machine

Precise Micro Hole Applications

EDM HX100

Hexon EDM Drill Machine Offers Fabrication of Superior Precise Micro Holes across a wide range of materials. We Provide Affordable Solution to produce good quality Small holes. We offers Customization in EDM Drill As per requirement

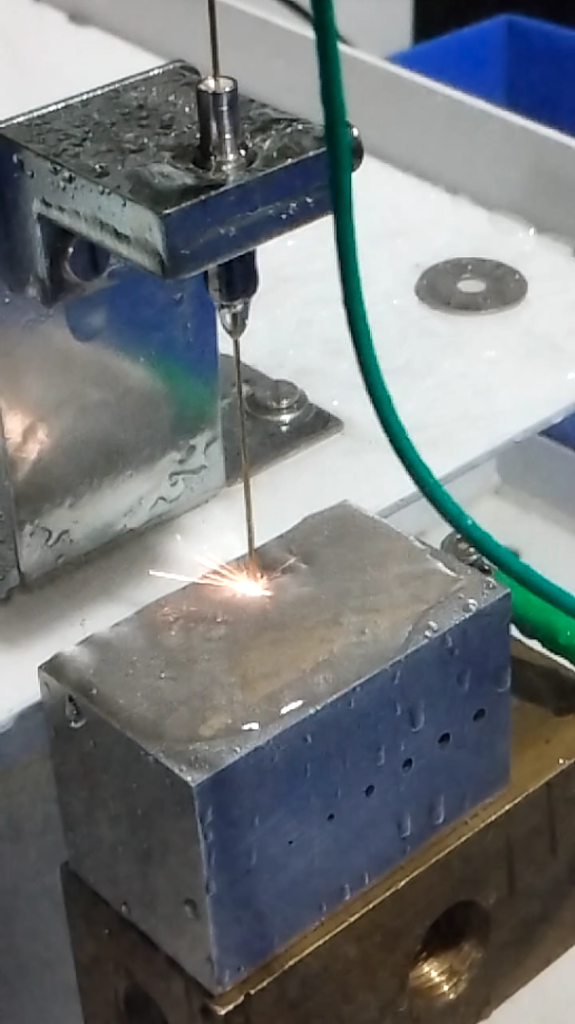

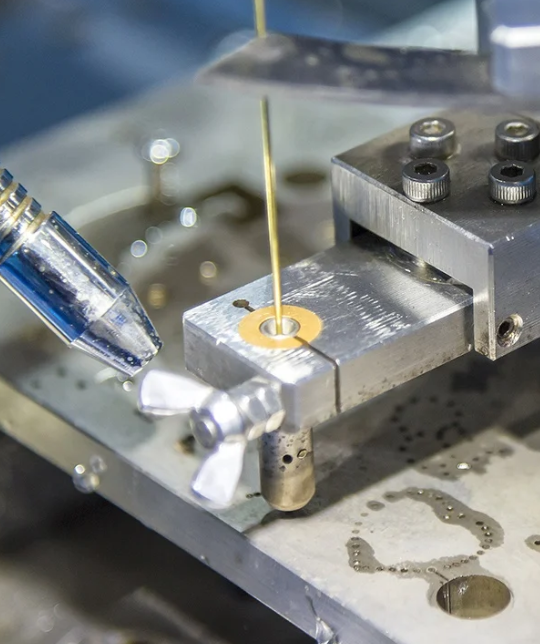

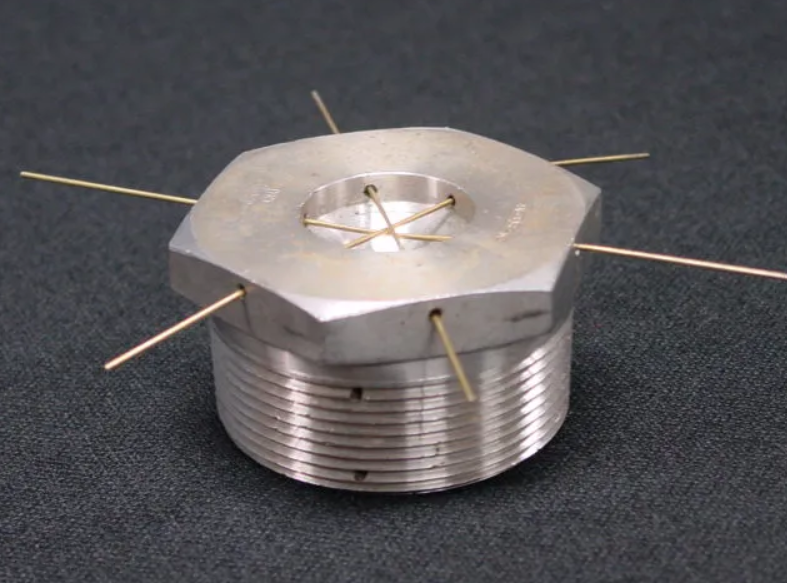

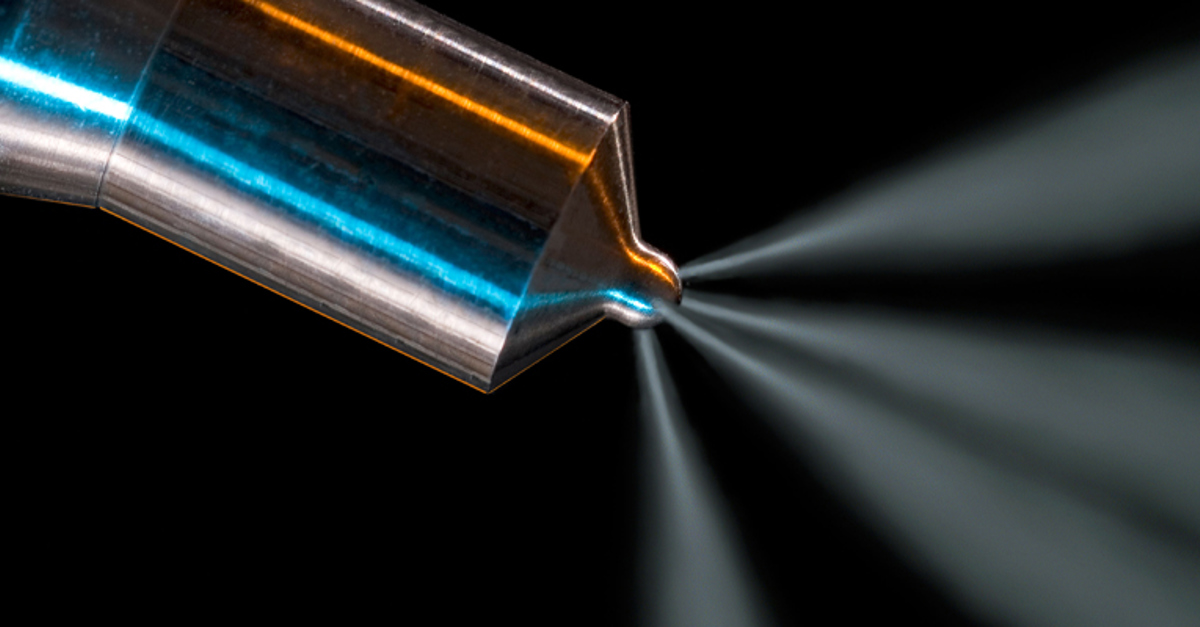

The process of EDM hole drilling involves employing a charged, rotating tube electrode along with intense flushing at high pressure to achieve rapid and precise machining of small, deep holes in conductive metals. Hexon EDM drilling machines are meticulously crafted to deliver exceptional levels of accuracy, reliability, and productivity, providing distinctive solutions particularly well-suited for high-volume production applications.

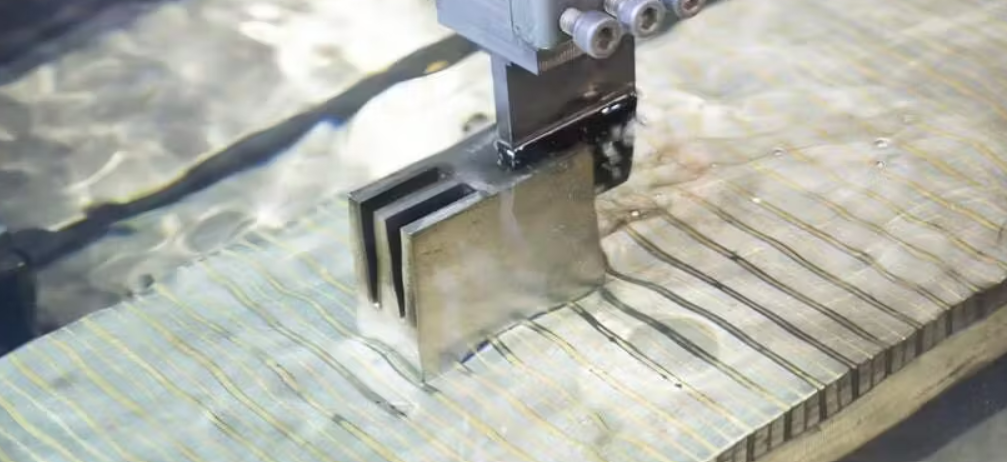

HEXON EDM HX100 drill machine is extensively employed for initiating holes, especially in aerospace applications such as aircraft engines and gas turbines used in energy production. In these contexts, cooling holes are essential to generate a protective film of cooling air on the turbine blades and vanes, preventing them from melting. Thanks to its four-axis configuration, the machine is capable of drilling holes at various angles on an inclined surface workpiece.

APPLICATIONS

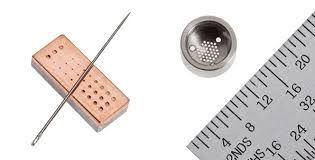

Compact Micro-drilling system

Cooling holes on turbine blades

Micro patterning of Die

lubrication holes

Micro nozzle

Die Sink EDM

SPECIFICATIONS OF EDM

- Travel Path ( X/Y/Z ) mm 300/300/100 (Customizable)

- Electrode Diameter mm Φ0.2- 3mm

- Max Workpiece Dimension ( L x B x H ) inch 22 x 14 x 10

- Machine Dimensions ( L x B x H ) inch 41 x 31 x 74

- Overall weight of the Machine kg 135

- Tank Capacity l 50

- Smart HMI Display inch 10

- Power Unit — Transistor controlled RC generator or Pulse Generator.

- User Interface — Touch Screen, USB, RS-232

- Control System — Closed Loop

- Pump Motor Rating — Max working pressure = 130 bar Max flow rate = 12 lpm

- Power Input V 230

- Phase — Single