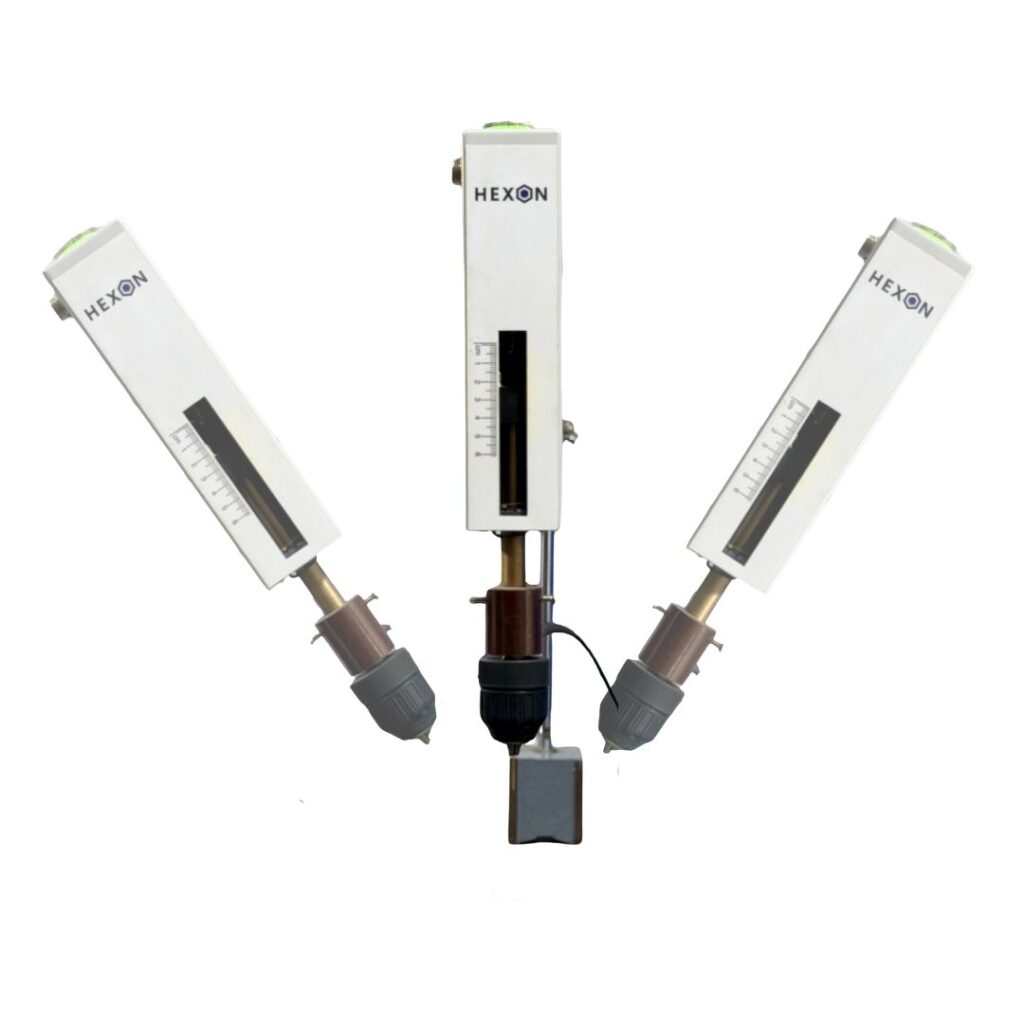

Portable EDM - Broken Tap Removal

Tap Drill Removal – Portable EDM

Precision. Portability. Zero Damage.

The Hexon Instruments Portable EDM Tap Drill Removal System is a powerful and reliable solution for removing broken taps, drills, reamers, and bolts without damaging the workpiece. Designed for on-site and workshop use, this compact EDM machine delivers high-precision material removal even in hardened metals.

Using advanced Electrical Discharge Machining (EDM) technology, the system erodes broken tools safely and efficiently—eliminating costly scrap, rework, and downtime.

Key Features

Non-Damaging Removal

Removes broken taps and drills without affecting threads or surrounding material.Portable & Compact Design

Lightweight and easy to transport for on-site maintenance and field operations.High-Precision EDM Technology

Controlled spark erosion ensures accurate and clean removal, even in hardened steel.User-Friendly Operation

Simple controls with minimal setup time—ideal for shop-floor and maintenance teams.Wide Application Range

Suitable for taps, drills, bolts, studs, reamers, and other broken tools.Energy Efficient & Reliable

Optimized power consumption with stable performance for continuous operation.

🔌 Electrical & Power

Input Voltage: AC 220V ±10%, 50/60 Hz (single phase)

Output Voltage: DC 90V

Control: Stepless current adjustment with auto feed and depth-stop functions

📏 Performance & Processing

Tool Removal Range:

• Broken tap/drill sizes: M2 to M6 (varies by variant)

• Electrode diameter range: 0.8 – 6 mm (approx.)Max Working Travel: ~50 mm (stepper controlled travel)

Depth Setting: Automatic stop at preset depth with auto-retract function

⚙️ Mechanical

Work Head: Adjustable/swivel work head with magnetic base for flexible positioning

Electrode Chuck: Accepts round, square or hex electrodes depending on application

Dielectric Fluid: Tap water (distilled/purified recommended)

📦 Dimensions & Weight

Machine Dimensions: ~300 × 400 × 100 mm (varies with variant)

Work Head Size: ~100 × 100 × 50 mm

Net Weight: ~16–22 kg

Portable Design: Lightweight, easy to move between workstations and job sites

📌 Features & Functions

✔ Quick start / one-button operation

✔ Automatic electrode feed & depth stop

✔ Auto-retract on depth limit

✔ Magnetic base for stable attachment to ferrous parts

✔ Works on hardened steels, alloys, copper and other conductive materials

🔧 Accessories (Typical)

Set of brass electrodes (round)

Magnetic base for work head

Water tank and pump (where applicable)

Power cable & control panel

📌 Industry Uses

Toolrooms & machine shops

Automotive and aerospace maintenance

Die & mold repair

Heavy fabrication and engineering

On-site field repairs