How to Operate and Care for Your Water Recirculating Chiller

Correct use and maintenance of your recirculating chiller can guarantee that the unit runs efficiently and the downtime is minimised. Poor maintenance may cause your chiller to lose its ability to maintain temperature, rendering it ineffective for certain applications. Correctly using and maintaining your chiller can extend its life and save your time and money on replacement costs.

This post will explain the steps that you can take to ensure your chiller lasts as long as possible. We’ll go into these in more detail below, but some of the things you can do are:

- Check temperature and humidity.

- Flush or top up the Refrigerant Fluid

- Dry Cleaning of Condenser

- Stainer cleaning and Replacement

- Clean or replace the filter

The frequency with which you need to complete maintenance tasks will depend on various factors. These include how often the chiller is used, the environment it’s situated in, and the type of coolant used in the system.

Let’s take a look at the above actions in a bit more detail.

1. Check temperature and humidity.

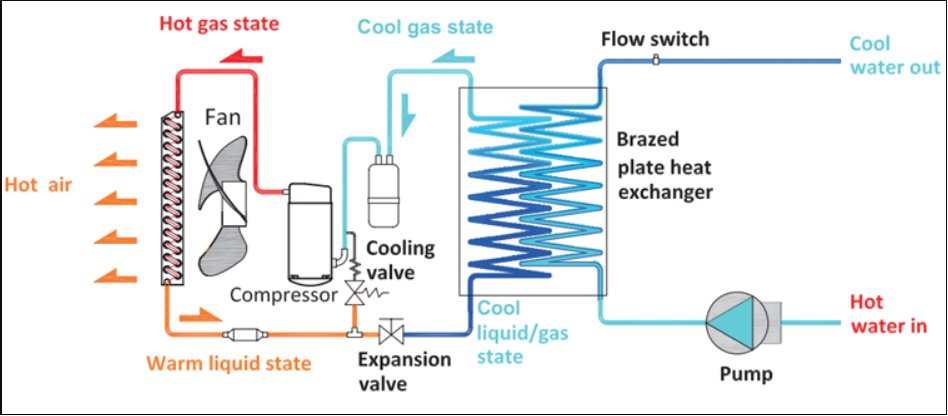

If the ambient temperature is outside of the optimal range (roughly 13 – 35°C), it could place a strain on electrical components or cause the evaporator to freeze and burst. Low ambient temperature (within the optimal range) can have a positive impact and boost efficiency. However, higher temperatures will result in less efficient heat transfer, a higher condensing pressure, and a reduction in overall system performance.

High humidity (above 80%) could cause condensation to form which, in turn, can damage electrical components.

2. Flush or top up the Refrigerant Fluid

Operating a machine with insufficient coolant could permanently damage the pump. The coolant level in the machine should be checked on a regular basis, once per week. The coolant should be replenished up as needed.

If the water has dropped dramatically in a short period of time, you may have a leak. External leaks will be easy to detect since coolant will be on the floor and maybe flowing from the chiller. Interior leaks may be more difficult to detect, but a significant decline in coolant level warrants further study.

Coolant should be cleansed and replenished at least quarterly, and more frequently for some devices. The frequency with which you must flush will be determined by the coolant used. Water, for example, allows algae to develop easily, and depending on the quality of your water, mineral deposits may form. While cleaning, utilising a particular bath cleaner can assist reduce the frequency with which you need to clean your bath without causing any harm.

Also, if you use water as your coolant, adding a corrosion inhibitor, such as ethylene glycol, can assist prevent corrosion of machine channels. Using an algae inhibitor will also help to prevent algae growth and reduce the need to purge the coolant more frequently.

3. Dry Cleaning of Condenser

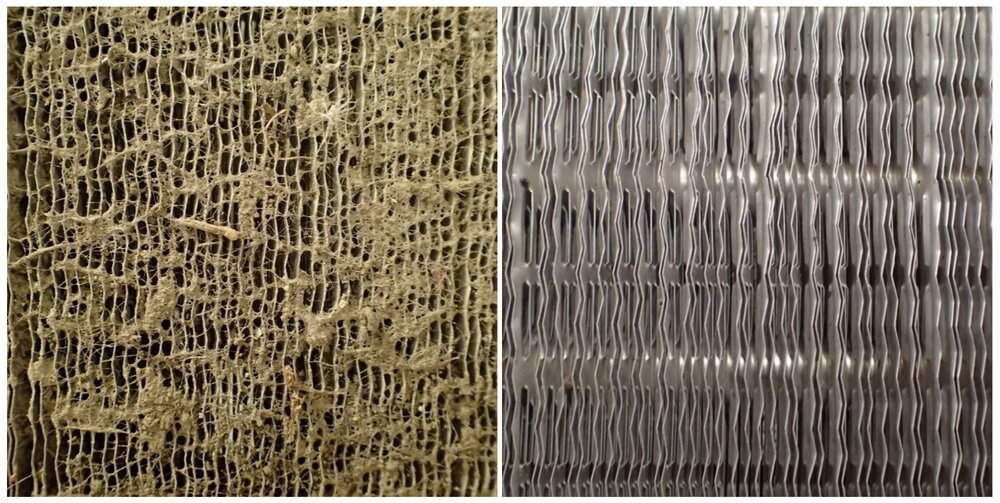

It is best to keep the chiller in as clean an atmosphere as possible. Even if your surrounding is clean well, dust and grime from the surroundings can accumulate on the condenser coil fins. This can obstruct air flow and reduce the machine’s cooling capability.

The fins should be checked on a frequent basis, possibly weekly in dustier environments. A fin comb, a paint brush, a hoover cleaner or compressed air can all be used to clean the fins.

4. Stainer cleaning and Replacement

Depending on the type of pump, a strainer may also need to be inspected and cleaned on a regular basis. The flow rate will be reduced if there is a buildup on the strainer. As a result, the pump will have to work more and will wear out faster.

Again, this will be model-dependent, so see your manufacturer’s instructions for further information.

5. Clean or Replace the Water Filter

If your chiller has a water filter, it’s a good idea to check it at least once a month. It is especially prone to accumulation during the initial period following installation. This can have a significant impact on performance in a surprisingly short period of time. In fact, it is advised that you inspect the filter for buildup the day after installation.

When such criteria are ignored, chiller selection becomes more difficult. This is where HEXON INSTRUMENTS research and studies come in handy to help find a solution.

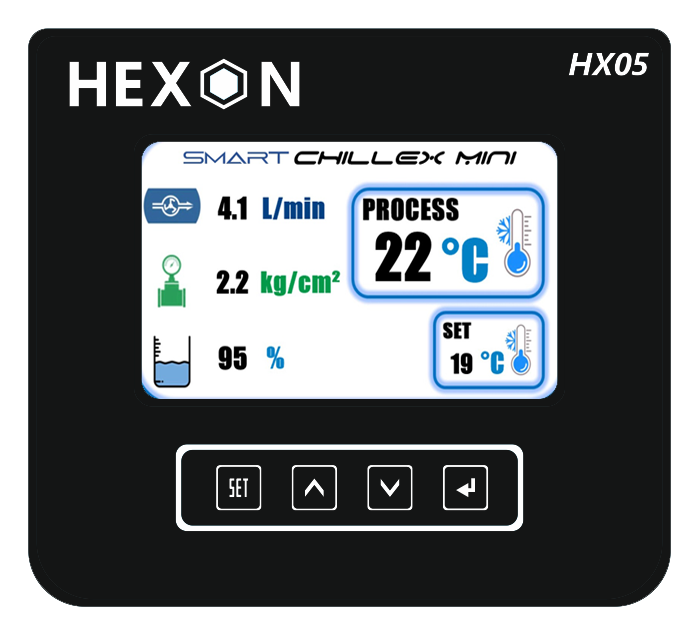

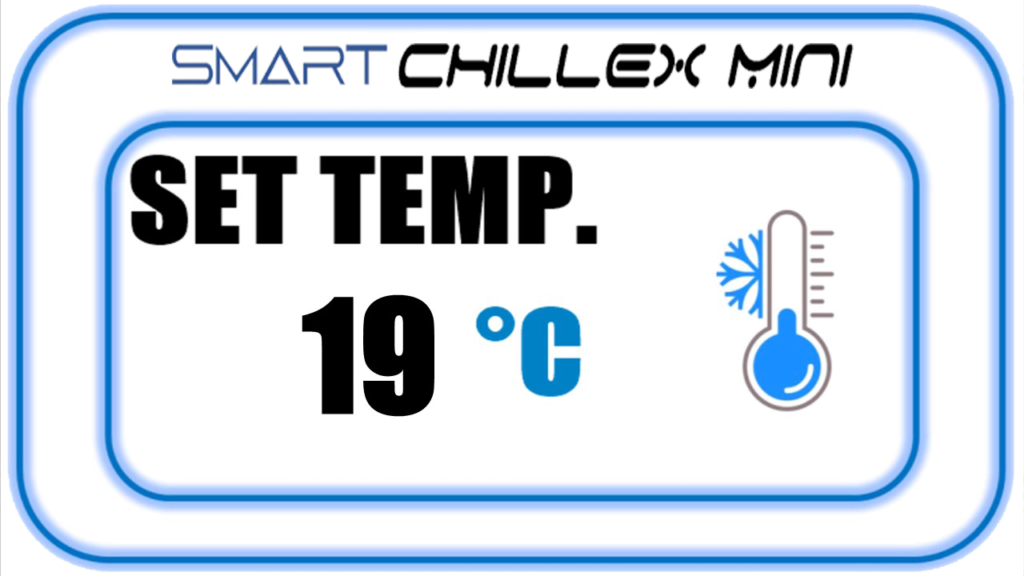

Hexon Instruments introduces the Smart Chiller, which is powered by a

This next generation smart chiller recognize and save the system components from damage.